Fluorescent Whitener Additive Compensation (FWA Compensation)

Introduction

To make paper look "whiter" without increasing the cost of

production, paper manufactures often employ a couple of different

techniques. One technique is to add "shading agents" to the paper,

that absorb a little of the middle wavelengths, thereby changing the

color of the paper to be a little less green. By far the most

powerful way of making the paper appear more white is to add

Fluorescent Whitener Additive (FWA, or Optical Brightening Agents -

OBA) to the paper. This is basically a fluorescent material that

absorbs light at Ultra Violet (U.V.) wavelengths, and re-emits it at

a slightly longer blue wavelengths. Subjectively something that

appears more blue, is regarded as being "whiter".

For more technical treatment of this topic, please refer to this

excellent paper: <http://www.axiphos.com/BrightnessReview.pdf>

Fluorescence

Fluorescent materials absorb light radiation at one wavelength, and

then almost instantaneously re-emit some of that energy at a longer

wavelength. Typical FWA absorbs wavelengths in the U.V. between

about 300 and 400 nm, and re-emit it between 400 and 460nm. The

visual effect of FWA depends on the amount of it present in the

paper, and the amount of U.V. in the illumination compared to the

level of normal, visible light. Generally better quality papers have

lower levels of whitening agents, and cheaper papers more.

Reflection Models and Spectro-colorimetry

The way a spectrometer measures the effect of ink on paper, depends

on a model of how an illuminant is reflected by the ink and the

paper. Typically a spectrometer instrument illuminates the sample

with a known illumination, often a incandescent tungsten lamp having

a color temperature of 2800 degrees Kelvin. It measures the

amount of light reflected by the sample at each wavelength, and then

converts that to spectral reflectance value between 0 and 100% by

dividing by it's measurement illuminant's intensity at each

wavelength. When it comes time to use that measurement to create an

ICC profile, the intensity of the assumed viewing illumination at

each wavelength (typically D50 for standard ICC profiles) is then

multiplied by the reflectance at each wavelength, and the overall

spectral reflectance is in this way converted into CIE tri-stimulus

values using an observer model.

So while the instrument measures with one type of light (type A, or

a white LED), it returns a measurement as if it had been measured

under a different kind of light (D50) by making use of a simple

model of light reflection off the media.

Notice that a key assumption of this simple model is that the light

that impinges on the sample at a given wavelength is reflected back

at exactly the same wavelength at a diminished intensity. Notice

also that any sort of fluorescent material (such as FWA) breaks this

model, since fluorescent materials emit light a different

wavelengths to which they absorb it. So the color measurements do

not accurately portray the appearance of the media when FWA is

present. A more complicated bi-spectral measurement (2 dimensional

spectral reflectance) is actually needed to fully characterize

fluorescent materials.

What Argyll's FWA compensation does

The FWA compensation function in Argyll improve on this simple model

of spectral reflection by taking into account the action of FWA. To

do this, it needs to measure the amount and nature of the FWA in the

media, and then have enough information about the viewing

environment to model how that FWA will behave.

To be able to measure the level of FWA in the media, the instrument

needs to be able to "see" the FWA in action, so the instrument needs

to be illuminating the samples with some level of U.V. Typically all

instruments do this, unless they have been fitted with a filter that

filters out any U.V. illumination (so called "UV cut" instruments),

or use an illumination source such as a "white" LED that doesn't

emit any U.V.

Such UV excluded instruments are not suitable for use with FWA

compensation.

The effects of FWA are modeled spectrally, so a spectral reading

instrument is also required.

Argyll can compute a model for the effects of FWA given the media's

spectral characteristics, and the illuminations spectral

characteristic, which must include the levels of U.V. in the

illuminant. Given these two things, Argyll can calculate how much

effect the FWA will have on the light being reflected and emitted by

the media under the intended illumination.

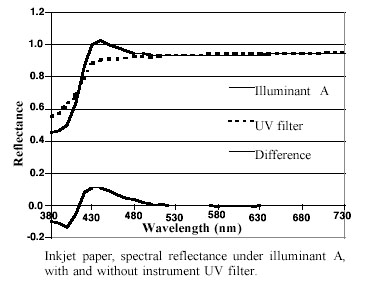

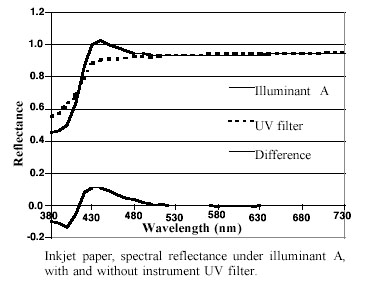

Ideally the level of FWA would be measured by comparing the paper

spectrum with and without U.V. present in the instruments

illumination. Because not all instruments allow these two

measurements to be done without some sort of manual intervention,

Argyll avoids the need for an FWA inactive (UV cut) or extra UV (UV

LED) measurement by employing a heuristic to estimate the FWA

inactive spectrum from the spectrum of the paper with FWA active.

Being a heuristic, it can sometimes be fooled by certain paper

colors into estimating more or less FWA content than is actual

present. The heuristic works best with high quality papers with an

essentially flat non-FWA enhanced spectrum. Papers with colored

tints or particularly off white appearance may not work well with

FWA compensation, unless the instrument has the capability of

measuring with two different levels of UV.

Note that typically in Argyll, if a viewing illuminant is specified,

then it is used for computing the appearance under that illumination

(CIE XYZ values), and if FWA compensation is used, then that same

illuminant will be assumed for the simulated measurement illuminant.

This results in measurements that better reflects the appearance as

the media as if it was being viewed under that illuminant, FWA

effects and all.

It is possible to also simulate the measurement of a media

under one illuminant, while then computing the tristimulus values as

if being viewed under a different illuminant, but this scenario is

only really useful for reproducing standardized measurement

conditions such as ISO 13655:2009 M0, M1 and M2, and is less useful

than the normal FWA compensation scenario in modelling real world

situations.

[The Argyll FWA compensation algorithm is described in the paper: A

Practical Approach to Measuring and Modelling Paper

Fluorescense for Improved Colorimetric Characterisation of

Printing Processes", Graeme W. Gill, Proc. IS&T/SID

11th Color Imaging Conference,

Scottsdale, Arizona; November 2003; p. 248-254, and was first published on December 2, 2002

in the argyllu_2002_12_02 source code. ]

Using FWA Compensation with proofing

The most common situation for employing FWA compensation, is in

proofing. This is when you have one printing device, the target (say

a printing press), and wish to emulate the behaviour of it with a

different device, the proofer (say an inkjet printer). The aim is to

be able to put both prints next to each other in a viewing booth,

and have them look identical. Typically the printing process, the

inks, and the media will be different between the target device and

the proofer. The aim of applying color profiling is to compensate

for these differences. Since the printing process can only darken a

white media, the selection of the proofing stock is critical.

Ideally it should be exactly the same color as the target, or if not

possible, lighter, so that the proofer can tint the proofing media

to match the target. If the two media had identical levels and types

of FWA in them, then there would be no need to use FWA compensation,

since the appearance of the media would match under any viewing

condition. Typically though, the levels and types of FWA are

different between the target paper and the proofing paper. A

limitation imposed by tri-stimulus colorimetry is that the

differences between the two media, inks and FWA can only be

compensated for perfectly, under a fixed and known illuminant.

By allowing Argyll to model the effects of FWA for both the source

profile (the target device), and the destination profile (the

proofing device), the effects can be accounted for, modeled

accurately, and incorporated in the profiles, so that a subsequent

transformation from source to destination device spaces using

absolute colorimetric intent, achieves a (hopefully) perfect

colorimetric reproduction. Since this is a closed system, where both

the source and destination profiles are made for each other,

non-standard parameters such as illuminant and observer models can

be used, as long as they are the same for both profiles. For

proofing, FWA should be applied identically to both profiles, by

specifying the same illuminant, and (optionally) the same observer

model.

[ In practice it is possible to compensate for the color shift that

results in viewing the media under non-D50 illumination or using a

non 1931_2 observer, or allowing for FWA effects without severe

incompatibility because all rendering intents except absolute

rendering normalize to the media color, rendering the media white as

white, even though the absolute values are not measured using a D50

illuminant. ]

Using FWA compensation for single, general use profiles

For creating ICC profiles that will be interchanged with other

unknown ICC profiles, or used with non-print source or destination

profiles, there is less flexibility, since ICC profiles by

convention assume that all media is being viewed under D50

illumination. The implication of this is that to be fully

interchangeable, it's not really possible to make the profile for

your actual viewing environment. Note that the D50 values that are

calculated without FWA compensation do not actually reflect the

appearance of a media under real D50, because they fail to take into

account the different levels of FWA activity between the

illumination using by the instrument to measure the media, and real

D50. To allow for this and actually meet the letter of the ICC

specifications, FWA compensation should ideally be used when

building a interchangeable ICC profile, by selecting the D50

illuminant, and the 1931_2 observer model (ISO 13655:2009 M1). Note

however that unless you are interchanging with profiles made using

M1 measurement mode data, that this is likely to make profiles less

interchangeable rather than more, since few if any profiles made

with older instruments will represent the appearance under real D50,

since few if any of those instruments use a real D50 illuminant that

will trigger the correct level of FWA response, and few if any other

packages will compensate for the differences in FWA activity between

the instrument illuminant used and real D50 (ie. most instruments

return M0 measurements by default, and older instruments are

generally not capable of M1 measurement).

Similarly, the effects of viewing the media in an environment with a

UV filter fitted over the D50 illuminant can be simulated by using

FWA compensation with the D50M2 illuminant, and the 1931_2 observer,

thereby simulating the results one would get if the media had been

measured with a "UV cut" type instrument, although such profiles are

not technically ICC compatible.

Measuring the illuminant

For FWA compensation to work well, it is necessary to know what the

spectral shape of the illuminant used for viewing is. While many

instruments provide an illuminant measurement capability over the

visible spectrum, for FWA compensation it is desirable to know the

Ultra Violet (UV) component of the illuminant. Few color instruments

are capable of reading to such short wavelengths though (the JETI specbos 1211 is an

exception). Argyll provides an indirect way of estimating the UV

component of an illuminant using its illumread

utility. Using illumread in combination with FWA compensation is the

recommended approach to modelling real world appearance of paper

containing FWA.

FWA myths

Amongst the user (and to some degree) vendor community, there has

been a widely held belief that the solution to fluorescent whitener

affecting color profiles is to simply use a UV filter fitted

instrument. Exactly what the origin of the legend is, is hard to

tell. Possibly it is a misinterpretation of the ANSI

CGATS.5-1993 Annex B recommendations for measuring the impact of

fluorescent effects, a translation of some of paper whiteness

measurement standards into the color profiling world, or possibly in

some common situations, if the viewing environment is very poor in

UV, then adding a UV filter to the tungsten instrument illuminant

makes for a better instrument/viewing illuminant match. There seems

to be no scientific or practical basis for believing that a UV

filter fitted instrument magically makes all FWA induced problems go

away.

Instrument UV filters

Note that to be able to measure the FWA in the paper, the instrument

has to be able to trigger Fluorescence, which it cannot do if it is

fitted with a UV filter, or uses a light source that emits no UV

(e.g. a normal white LED). So UV excluded instruments are not

suitable for use with FWA compensation.